Piston Compressors? It's Old Tech. Introducing the new

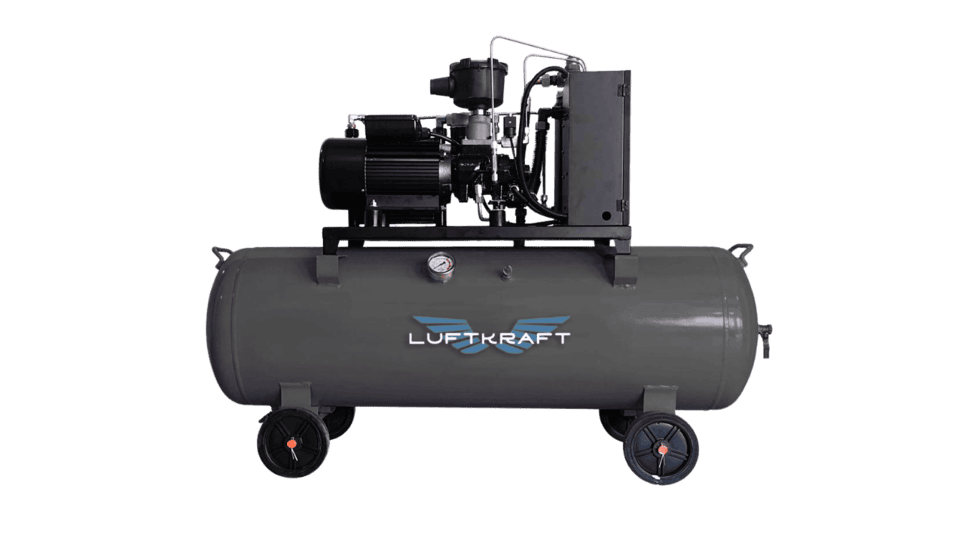

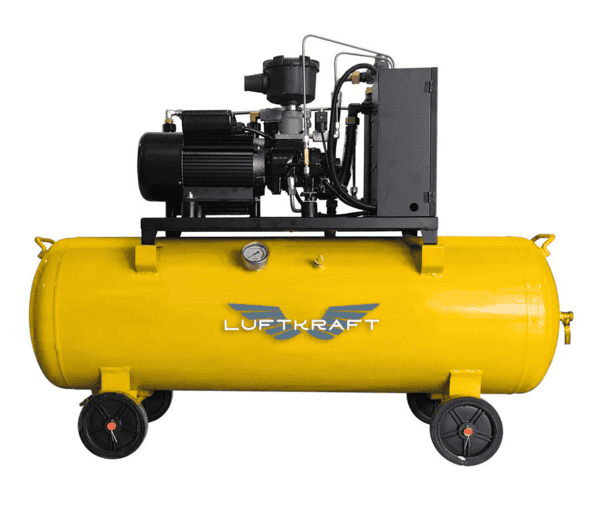

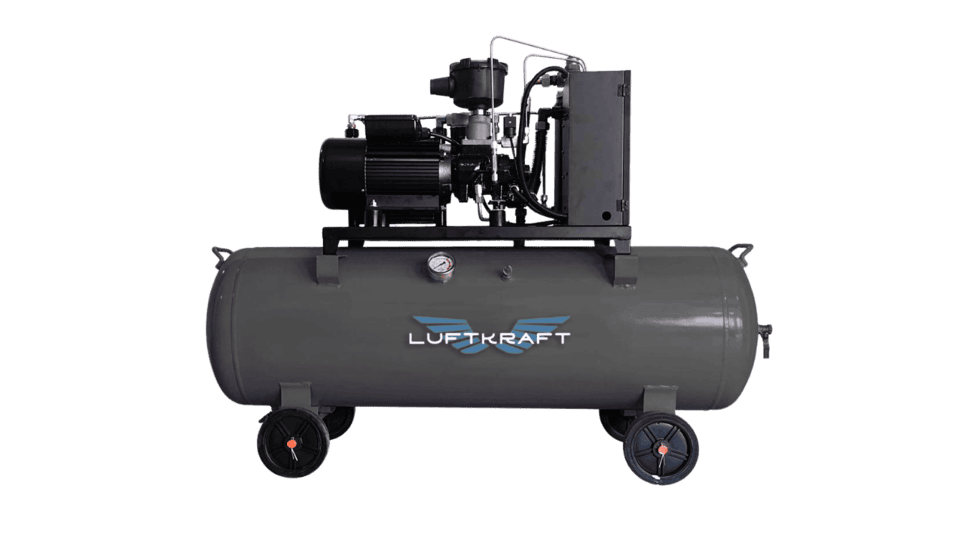

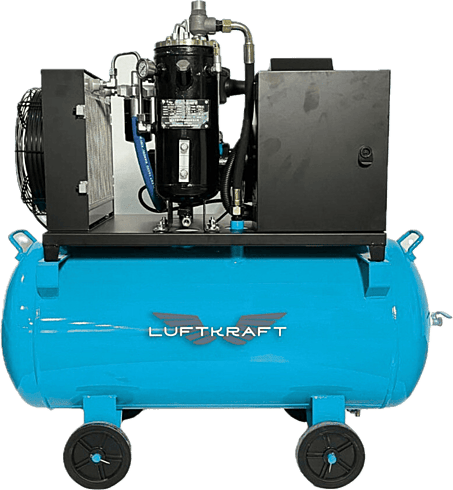

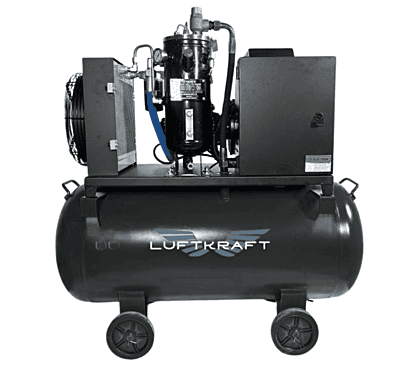

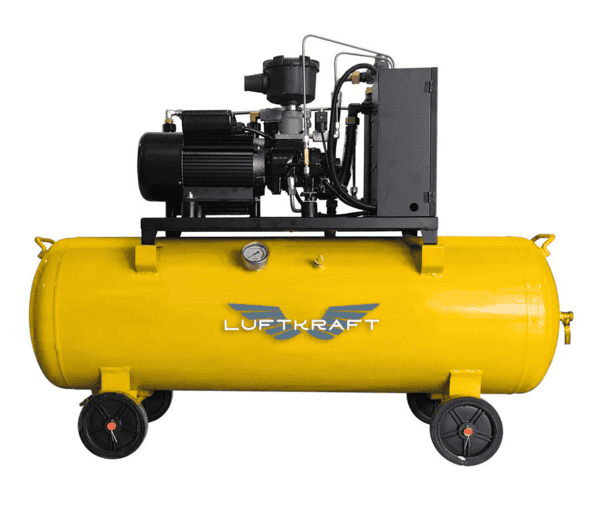

LuftKraft Tank Mounted VSD Screw Compressors

Power-packed in a compact form, ready to perform

Features of LuftKraft Tank Mounted Screw Compressors

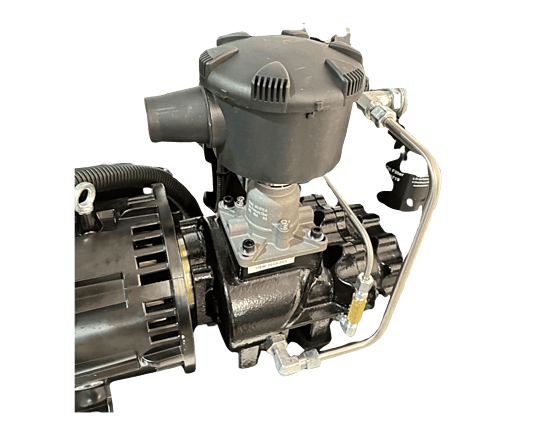

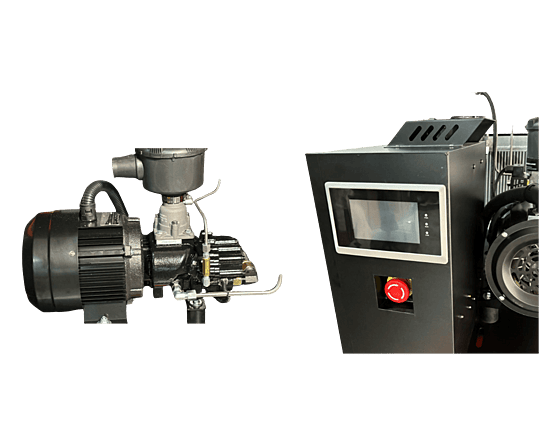

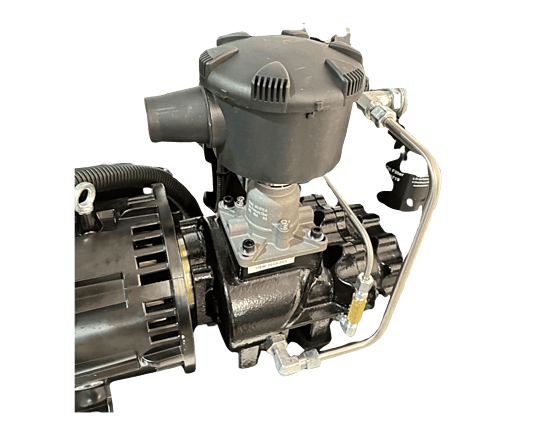

Energy-Efficient VSD Technology:

Our compressors feature VSD (Variable Speed Drive) technology that adjusts motor speed based on air demand, reducing energy consumption and increasing operational efficiency.

Quiet Operation

Thanks to the advanced design, these compressors operate quietly, offering a more comfortable work environment and continuous operations

Compact & Space - Saving

Integrated with a tank, our compressors save valuable floor space and offer easier installation without the need for additional air storage.

Designed for long-term reliability, Luftkraft tank-mounted screw compressors are easy to maintain with fewer components to service, lowering maintenance costs

Industries Served with our LuftKraft Tank Mounted Air Compressors

Luftkraft’s tank-mounted screw compressors serve a wide range of industries, providing consistent, efficient air to support production lines, machinery, and heavy-duty tools.

Car Garages

In car garages, Luftkraft compressors deliver the necessary power for a wide variety of tasks, from running pneumatic tools like impact wrenches to operating vehicle lifts and air conditioning systems. Designed for high durability and efficiency, our compressors support automotive repairs, maintenance, and diagnostics, helping businesses maintain productivity and reduce downtime.

Manufacturing

Luftkraft compressors are widely used in manufacturing industries to power pneumatic tools, assembly lines, and production machinery. Our compressors provide consistent, high-quality air for precision manufacturing, reducing downtime and improving overall production efficiency, while being energy-efficient and low-maintenance.

Carpentry Workshops

Luftkraft compressors are ideal for carpentry workshops, providing reliable air pressure for tools like pneumatic nailers, sanders, and saws. Our compressors ensure smooth operation and help craftsmen achieve precise cuts, finishes, and joins, enhancing overall productivity while reducing energy consumption and maintenance needs.

Hospitals

Luftkraft compressors provide a reliable and continuous supply of medical air for hospitals, ensuring the smooth operation of critical equipment such as ventilators, surgical tools, and air-driven systems. Our compressors meet stringent hygiene standards and operate efficiently, supporting the healthcare sector in maintaining a safe and clean environment for patient care

Food Processing

In food processing, Luftkraft compressors play a critical role in powering machinery used for packaging, mixing, and conveyor systems. They are designed to meet the high hygiene standards required in food production, offering efficient and safe operation while reducing operational costs and minimizing contamination risks.

Constructions

On construction sites, Luftkraft compressors provide the power necessary for tools like jackhammers, drills, and pneumatic systems. Built for tough environments, our compressors ensure reliable performance, even under heavy-duty conditions, supporting construction projects with steady and efficient air supply for all equipment

Product Category

LK-1P-2.2KW

- Pressure (Bar): 8-10 Bar

- Exhaust Volume(m3/min): 0.3

- Power(KW/HP): 2.2kW /3HP

- Dimension(mm): 1340*450*1030

- Noise dB(A): ≤60±2

- Weigt(kg): 116

- Pipe Diameter: G1/2

- Startup Mode: Direct Start

- Gas Tank(L): 160,

- Power Supply: 220V

LK-3P-4.5KW

- Pressure (Bar): 8-10 Bar

- Exhaust Volume (m3/min): 0.62

- Power(KW/HP): 4.5kW (6 HP)

- Dimension(mm): 1170*510*1090

- Noise dB(A): ≤62±2

- Weigt(kg): 154

- Pipe Diameter: G1/2

- Startup Mode: Variable Synchronous Start

- Gas Tank(L): 180

- Power Supply: 380V/50HZ,

LK-3P-7.5KW

- Pressure (Bar): 8-10 Bar

- Exhaust Volume(m³/min): 1.0

- Power(KW/HP): 7.5 kW /10 HP

- Dimension(mm): 1400*510*1090

- Noise dB(A): ≤68±2

- Weigt(kg): 177

- Pipe Diameter: G1/2

- Startup Mode: Direct Start

- Gas Tank(L): 230,

- Power Supply: 380V/50HZ,

Why Choose LuftKraft Tank Mounted Screw Compressors?

By adjusting the speed of the motor to match the air demand, our VSD technology can save up to 35% in energy consumption, making these compressors a cost-effective choice for long-term operations.

Unlike piston compressors, Luftkraft’s tank-mounted screw compressors deliver continuous, uninterrupted performance with no downtime, ensuring reliable air supply for even the most demanding applications.

The integrated tank design of Luftkraft’s compressors offers the flexibility of compact installation without compromising performance, making it ideal for businesses with limited space. Combining the compressor and tank into a single unit reduces the need for separate installations, optimizing floor usage and enhancing efficiency. Perfect for tight workspaces, this space-saving structure ensures easy transport and setup, providing a hassle-free and reliable solution for diverse industrial applications.

With robust construction, our compressors offer reliable performance in various industries, reducing the likelihood of breakdowns and unscheduled downtime. Built to withstand demanding conditions, they ensure consistent operation even in heavy-duty environments. This durability translates to lower maintenance costs and increased productivity, making them a dependable choice for long-term use.”

Why should you choose a VSD Screw Compressor Over A Piston Compressor?

| ADVANTAGE | PISTON COMPRESSORS | LUFTKRAFT VSD SCREW COMPRESSORS |

| Continuous Operation | Requires frequent cooling periods to prevent overheating. | Provides steady, uninterrupted air supply, ideal for continuous use. |

Energy Efficiency | Operates at constant speed, leading to higher energy consumption. | VSD technology adjusts motor speed to match demand, saving energy. |

Quiet Operation | Produces significantly more noise due to reciprocating motion. | Operates with minimal noise due to advanced screw design. |

Low Maintenance | Requires frequent servicing due to higher mechanical wear. | Fewer moving parts result in lower maintenance needs and longer intervals. |

| Consistent Air Quality | May produce air with fluctuations and impurities. | Delivers pulsation-free, high-quality air suitable for precision tasks. |

Durability and Longevity | Experiences more wear and tear, reducing lifespan. | Built for heavy-duty use, offering a longer lifespan. |